View Mobile Number

clarionmachines@gmail.com +91-9423964935

5.50 Lac - 75 Lac / 1 set

| Business Type | Manufacturer, Exporter, Supplier |

| Specifications | |

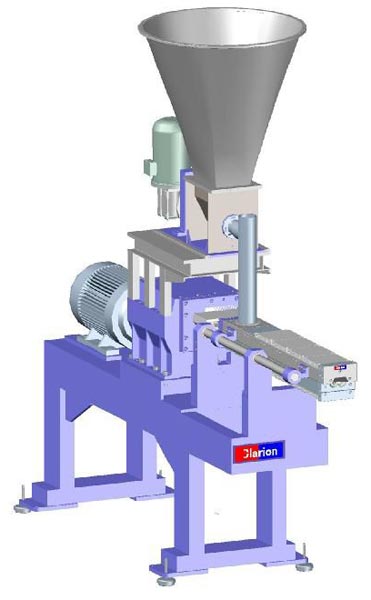

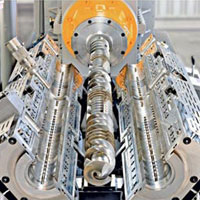

| Type | Twin Screw Extruder |

| Certification | CE Certified |

| Click to view more | |

Product Details

Application

Handling Industries

Weight

10-100kg

Color

Mulit Colour

Voltage

220V

Capacity

100kg/hr

Frequency

60Hz

Automatic Grade

Automatic

Power

10-15kw, 15-20kw

Driven Type

Electric

Warranty

1yrs

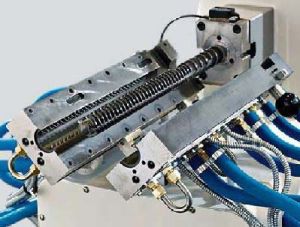

Indulged in the customers’ needs with excellence, we are involved in offering Twin Screw Extruders. We make them available in any size as per the requirement of the customers. Their effective design makes them easy to clean and produces better results of heavy as well as light mixing. They are made of special steel which is renowned for its high wear resistance. It is easy to change their complete element screw shaft.

Basic Features :

- Very Economically priced

- robust & strong design of Gear box for heavy duty Kneading at High Speeds

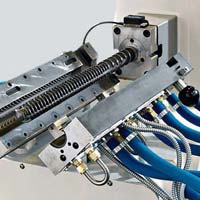

- Machine barrel is CNC machined for Water Cooling Jacket for effective cooling

- Easy to clean design

- All Individual Controls for heaters & cooling section for accurate Temp. Control

- Additional (Thermal) Heat transfer unit provided for energy savings

- Gear Box is fitted with Oil Circulating Cooling Pump

- Very Effective design for better Result of heavy as well as light mixing

- Segmented Screw Elements & liners to reduce the wear & tear operating cost

- All wear parts Are manufactured from a very Special Steel for High Wear resistance.

- Also Coated for better wear life.

- Easy for changing of complete Element screw shaft

- Very Wide range of production Capacity for Powder Coatings Section from 5 Kg/ hr.

- To 1250 Kg/Hr. Machines.

- Very strong design back up all machines technology upgradation.

Special (optional) Features :

- Thru Cooling for twin Shaft

- Segmental barrel

- Additional feeding Points

- Special design Elements

- High feed rate elements

- water Heating System in place of electrical

- heaters

- Additional process length

Looking for "Twin Screw Extruders" ?

Set

Explore More Products